Alloy Wire International

Datasheet: Stainless Steel 302

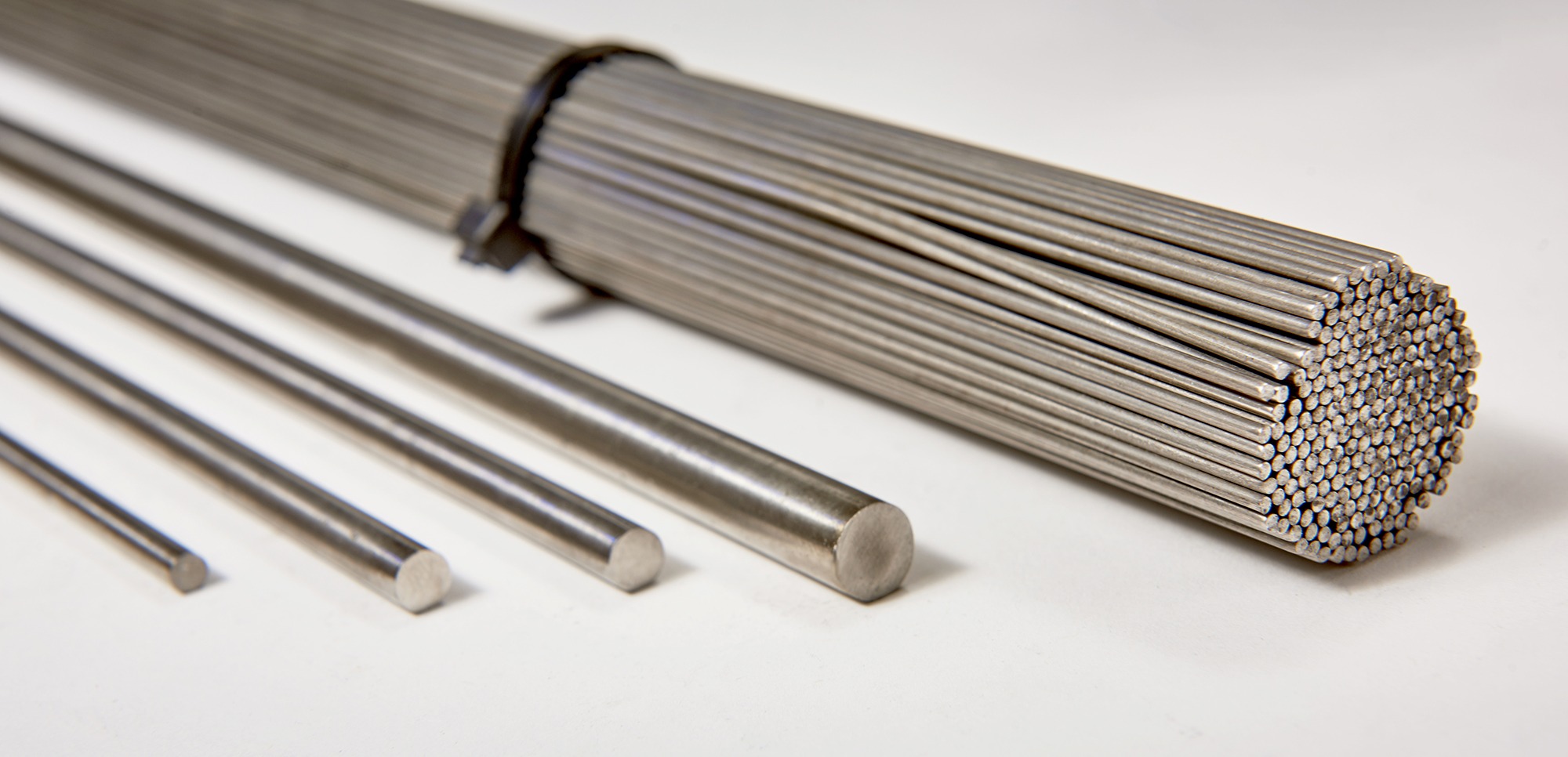

Stainless Steel 302

Stainless Steel 302 has good mechanical properties and corrosion resistance, and is well known for its ease of fabrication and formability.

Stainless Steel 302 is also known as AISI 302.

Available in all profile options

Key Features

Stainless Steel 302 offers the following key features:

Good mechanical properties and corrosion resistance

Typical Applications

Stainless Steel 302 is known to be suitable for the following applications:

Springs

Engineered components

Wire mesh

Wire cloth

Hose braiding

Designations

W.Nr 1.4310

UNS 30200

AWS 160

Specifications

AMS 5688

ASTM A313

ASTM A580

BS 970

BS 2056

Chemical Composition

The chemical composition of Stainless Steel 302 is indicated in the table below:

| Element | Min % | Max % |

|---|---|---|

| C | – | 0.12 |

| Mn | – | 2.00 |

| P | – | 0.045 |

| S | – | 0.03 |

| Si | – | 1.00 |

| Cr | 17.00 | 19.00 |

| Ni | 8.00 | 10.00 |

| Fe | BAL |

Alloy Details

Stainless Steel 302 density, melting point, coefficient of expansion, modulus of rigidity, and elasticity is indicated in the table below:

| Density | Melting Point | Coefficient of Expansion | Modulus of Rigidity | Modulus of Elasticity |

|---|---|---|---|---|

| 8.0 g/cm³ | 1420 °C | 17.6 μm/m °C (20 – 100 °C) | 70.3 kN/mm² | 187.5 kN/mm² |

| 0.289 lb/in³ | 2590 °F | 9.8 x 10-6 in/in °F (70 – 212 °F) | 11000 ksi | 27195 ksi |

Heat treatment of finished parts

The typical heat treatment of Stainless Steel 302:

| Condition as supplied by AWI | Type | Temperature | Time | Cooling |

|---|---|---|---|---|

| Annealed or Spring Temper | Stress Relieve | 250 °C (480 °F) | 1 Hr | Air |

Properties

The typical mechanical properties of Stainless Steel 302:

| Annealed | ||

|---|---|---|

| Approx. tensile strength | <800 N/mm² | <116 ksi |

| Approx. operating temperature | -200 to +300 °C | -330 to +570 °F |

| Spring Temper | ||

|---|---|---|

| Approx. tensile strength | 1300 – 2200 N/mm² | 189 – 319 ksi |

| Approx. operating temperature | -200 to +300 °C | -330 to +570 °F |

The above tensile strength ranges are typical. If you require different please ask.